The hole over the corner greatly simplifies finding the actual corner of the stock material. A

center-of-hole finding routine is simpler and more repeatable than any other

method, and having it directly over the material corner is very convenient. This

tool is particularly useful for creating a repeatable reference point for your

workpiece, especially if the tool breaks or needs changing.

The edge finder's open corner design accepts small deformities in the work stock

and minimizes buildup of dirt and chips that limit accuracy and repeatable

measurements.

The smaller 3/8in. (9.52mm) hole over the corner is suitable for use with 1/4" (6.35mm) and 1/8" (3.175mm) probes, and is

centered directly over the corner. The larger hole is 0.75" (19mm) diameter and is

suitable for larger probes or tools, and is 0.5" x 0.5" (12.7mm x 12.7mm) from the material

corner. The large hole also makes handling the edge finder easier. This edge

finder is large enough to easily handle and place for measurement, yet small

enough to avoid most work holding clamp arrangements. It is 1/4" thin to

allow use in limited space and offers a 0.10" deep pocket for a reliable alignment

with your material. The top surface makes a great way to find the top of

the material without risking damage to the work surface.

To use the edge finder, connect a ground wire to the edge finder and clip the

sense wire to your probe (or router bit) and implement a center finding routine.

The routine should: first: find x-, then x+, calculate center of x as zero, go

to x=0; second: find y-, then y+, calculate center of y as zero, go to y=0;

third: repeat find center of x- & x+; optional: repeat find center of y- & y+.

Always seek either x- or y- first, because if you forget to connect the sense

wire (or the wire breaks), it will only push the edge finder off the material

instead of breaking something before you can stop the process.

Note: if the tool

happens to be grounded through the spindle, connect the sense wire to the

edge finder.

Three way sensing of the edge or corner:

1) Center finding using the smaller hole. Center is directly over the corner.

2) Center finding of the larger hole. Center of 0.75" hole is 0.5" x 0.5" from material corner

3) Edge finding using outside surface edge is 0.30" (7.62mm) from outside surface.

The top surface can also be used to find the top of the material. The Aluminum is machined to 0.150" (03.81mm).

Note: User is responsible for verifying the dimensions to the edges and hole centers.

The machining will vary slightly from unit to unit.

The default settings in the Mach3 HiddenScript file will produce reasonable and consistent results.

GRBL users will need to enter the operating offsets into their cotroller program manually.

Installation information and software:

For Mach3 users: Below is a Sample file (HiddenScript.m1s). This is a text script file that is to be loaded into

the Mach3 "Auto Tool Zero" button. This file is compatible for both mm and inch modes.

The file can be used, as is, or to create your own routines that fit your special needs.

EdgeFinder_setup.pdf Will help you to istall the files.

The 1024A.set and 1024B.set files are screen image files identical to the default Mach3 main screen (1024.set) with the addition of a convenient

touch status indicator.

=== === The latest Mach3 files. === ===

EdgeFinder_setup.pdf (1.0MB) - (Read me First)

MACH3 Main screen file 1024D.set (108KB) - (2020/3/6) - Copy into mach3 root directory.

Edge-Finder_Options.htm (25KB) - (2022/3/23) Help file in English - Copy into mach3 root directory

HiddenScript_220318.m1s.txt (52KB) - (Open as text file and paste into button scrip - See "Operator/Edit Button Script")

Customizing the HiddenScript 220309.pdf (724KB).

Please note: The Mach3 script file will probably need some adjusting of some parameters in order to meet your EdgeFinder dimensions.

EdgeFinder Compass_en.jpg Graphic for Edge Finder Commands - Copy into mach3 root directory.

=== Für meine deutschen CNC-Freunde. ===

HiddenScript_220318_dt.m1s.txt

(Als Textdatei öffnen und in Schaltflächenskript einfügen - siehe "Operator/Edit Button Script")

Anpassen der HiddenScript 220309_de.pdf

Edge-Finder_Options(deutsche).htm (2022/3/1) -

Hilfedatei in Deutsch - Ins mach3-Root-Verzeichnis kopieren und umbenennen in "Edge-Finder_Options.htm"

EdgeFinder Compass_de.jpg (2022/3/22) - Grafik für Edge Finder-Befehle - Ins mach3-Root.

EdgeFinder_setup_dt.pdf (940KB) 2022/3/28 - Lese mich zuerst.

autom. Kantenfinder.set 2022/4/6.

dt. Kantenfinder Mach3 Screen.txt 2022/4/6.

$MachScreenSettings 2022/4/6.

Bitmaps.rar 2022/4/6.

Screen.rar 2022/4/7.

dt. Mach3 Screen.pdf 2022/4/7 - Installationshinweise für Screen.rar.

=== Universal Gcode Sender. ===

UGS Macros wjv.txt (Possibly helpful Unversal G-Code Sender macros) (2KB)

Note: UGS does not support temporary registers in the macros.

This makes edgefinder macros very hard to do.

The built-in edgefinding routine needs to be updated to support finding the center of a hole.

=== Mach4 file. ===

mcTouchOff-180820.lua (MACH4 EdgeFindier Fixup - replaces early version of mcTouchOff.lua) (292KB)

=== Older files. ===

HiddenScript_220209.m1s.txt (50KB). -

(Open as text file and paste into button scrip - See "Operator/Edit Button Script")

CNC_Video_1.mp4 (6.1MB).

CNC_Video_2.mp4 (5.9MB).

Customizing the HiddenScript 191004.pdf (724KB).

CNC_EdgeFinder_Guide.pdf(1.8MB) (2018/5/8)

GettingTheMostOutOfTheEdgeFinder.pdf (603KB).

=== To change the subject a little. The following concerns Variable Frequency Drive (VFD) Setup ===

The following two files may help someone to set up their Variable frequency drive for their 400Hz spindle motor.

These files show both the default settings (220V 50Hz) and a sample set of settings for a 110V 400Hz 1.5KW spindle motor.

They should allow one to extrapolate the settings needed for any spindle motor On these VFDs.

The Chinese-to-English translation has been slightly Americanized to help add clarity.

Huanyang_3KW_VFD_190526.pdf (2.4MB).

YL620-A Setup table 190707.pdf (277KB). (Better English)

YL620-A Setup table.pdf (277KB).

Startup procedure for a spindle motor 190805.pdf (576KB).

Odds are we are all running our spindles wrong.

I have seen some complaints about their spindle motor taking a long time to get up to speed and to stop.

The motor is unloaded and has a fairly small mass. It should be safe to set the Accleration and Deceleration time to one or two seconds.

For the Huanyang, the variables are PD014 through PD021 with a Default of 20 seconds. I use 1.5 seconds with excellent results.

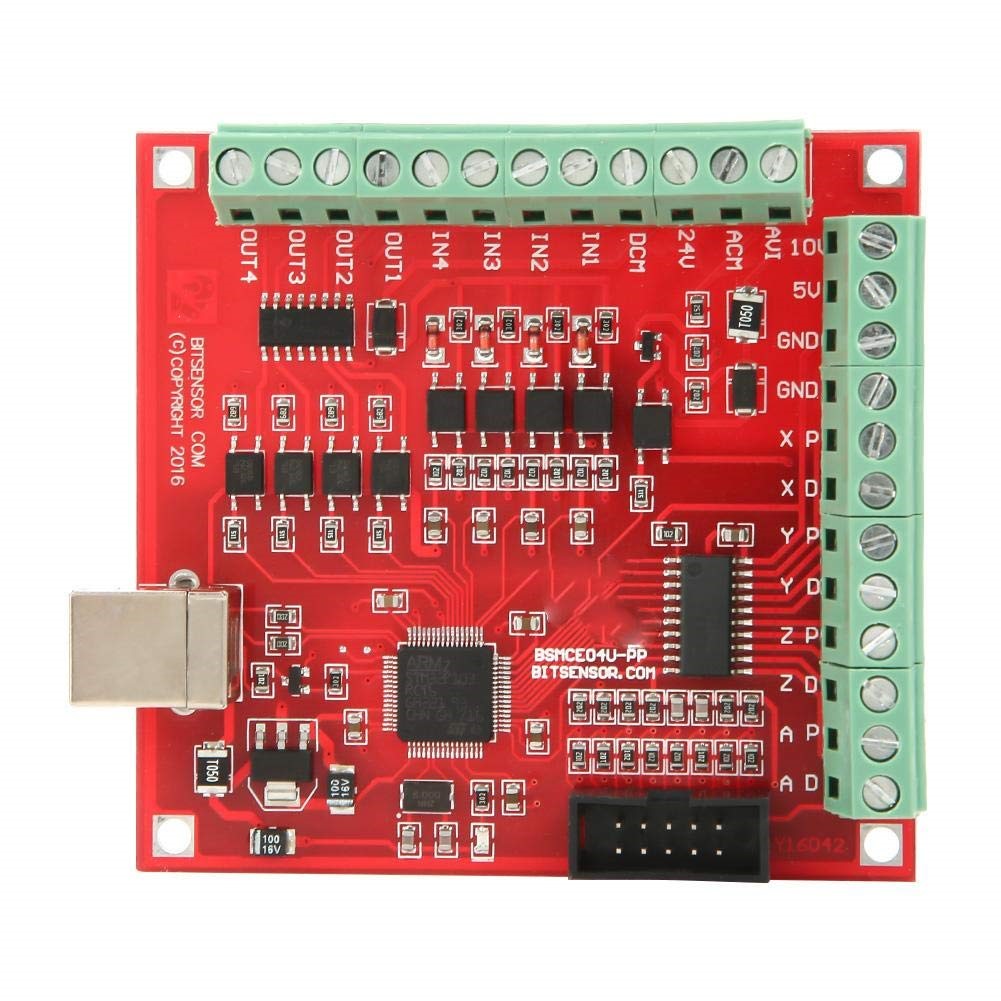

=== The BSMCEO4U-PP controller board User Guide (Americanized English) ===

This is the board I installed after my parallel port board died. It works well, when set up correctly. It supports limit switches, probes/touch-plates, a Variable Frequency Drive, and more.

The manual is my translation and clairification of the supplied Chinese manual.

The board runs via USB and has the following important properties:

1) The drive outputs for X, Y, Z, A, & Spindle Speed are all hard coded (Port & pin numbers are fixed and cannot be changed by the user). The user need only correctly set the stepper pulse and direction settings in Mach3.

2) All Input pins are on PORT3. There are 12 (twelve) available inputs. Only inputs IN1 through IN4 are isolated, and can be used for limit switches and probes.

IN5 to IN12 are Logic Level 5-Volts, normally used for a Handwheel.

3) All Outputs are on PORT3. There are 4 (Four) OUT1 through OUT4. Suitable for VFD ON/OFF, Flood, and Mist control.

4) Handwheel input uses PORT3 IN5 through IN12 and has 5Volt support.

Pinout for the handwheel is listed in Install Manual. (This feature may not work properly. I could get only one axis to work.)

5) The Analog/PWM Spindle Speed Output is completely isolated and requires connections to

ACM, AVI, & +10V. (Ground, signal, & voltage) to be supplied by the VFD for proper operation.

BSMCEO4U Install Manual 2.8.pdf.

Anyone see any errors in these documents? Please Let me know and I'll try to fix them.

Edge Finder Specifications:

Size:

2.7" (69mm) x 1.95" (50mm) x 1/4" (6.35mm) thick.

Small hole:

0.375" (9.5mm) dia. Offset from corner 0.00" x 0.00". Depth of hole for probe 0.15" (3.5mm).

Large hole:

0.75" (19.0mm) dia. Offset from corner 0.50" x 0.50" (6.35mm x 6.35mm). Depth of hole for probe 0.15" (3.5mm).

Pocket:

0.10" (2.54mm) deep.

Material:

Body: 6061 Aluminum; Screw: 6/32x1/4" steel.

Option:

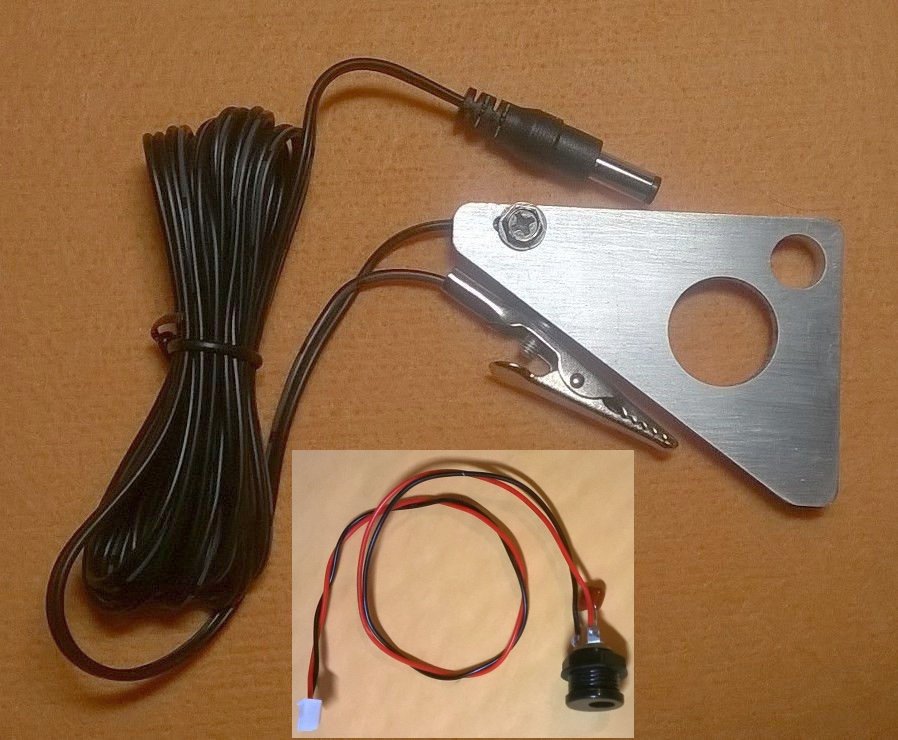

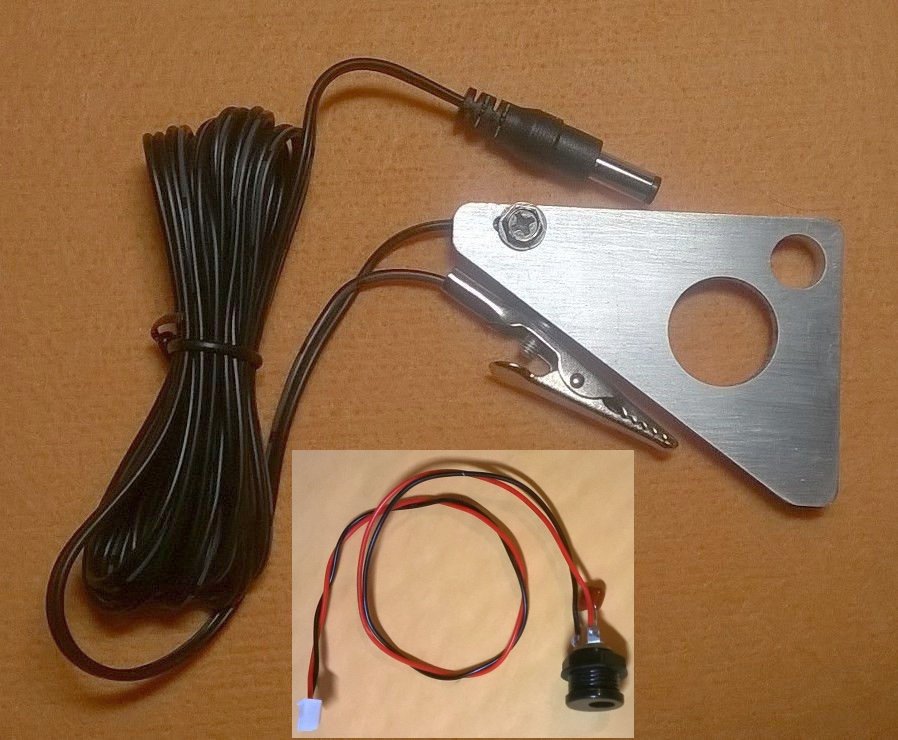

1) Model EF103: Comes with (New 2020/10/25) Magnetic clip, replacing the Alligator clip, 6ft. (1.8M) zip cord style wire,terminated with a 5.5x2.1mm barrel male plug.

Includes a female 5.5x2.1mm chassis connector with a 8 in. (200mm) cord and a JST 2.5mm plug and header.

2) Model EF104M: Comes with easy,fast, reliable Magnetic clip, 6ft. (1.8M) zip cord style wire, terminated with a GX12-2 male plug.

Includes a female GX12-2 chassis connector with a 8 in. (200mm) cord and a JST 2.5mm plug and header.

3) Magnet clip and 6ft (1.8M) wire cord (unterminated) sold separately. Fast, easy, and reliable electrical connection to spindle collet. (Cannot be purchased without an Edge Finder)

Contact: Vancura Innovations

Phone: +1.309.948.6120

emil: cnc-sales@vancura-innovations.com

Purchase On-line: With PAYPAL: sales@vancura-innovations.com

|

Item Name:

|

Item No.

|

Price:

|

|

Select Image to Enlarge |

One CNC Edge Finder 3x2

(USA Only) |

CNC-EF101U |

$21.99 |

|

|

CNC Edge Finder 3x2

(CANADA) |

CNC-EF101C |

$30.80 |

|

|

CNC Edge Finder 3x2

(Interntional) |

CNC-EF101I |

$35.75 |

|

|

CNC Edge Finder EF103 upgrade kit with Magnetic Clip, 6ft cord, & 5.5x2.1mm M&F connectors.

(USA Only) |

CNC-EF103 |

$34.79 |

|

|

CNC Edge Finder EF103 upgrade kit with Magnetic Clip, 6ft cord, & 5.5x2.1mm M&F connectors.

(Europe Postage) |

CNC-EF103(EU) |

$34.79

+

EU

Postage |

|

|

CNC Edge Finder EF104 upgrade kit with 6ft cord & GX12-2 M&F connectors.

(USA Only) |

CNC-EF104 |

$34.79 |

|

|

CNC Edge Finder EF104 Magnetic upgrade kit with 6ft cord & GX12-2 M&F connectors.

(USA Only) |

CNC-EF104M |

$35.65 |

|

|

CNC Edge Finder EF104 Magnetic upgrade kit with 6ft cord & GX12-2 M&F connectors.

(Europe Postage) |

CNC-EF104M(EU) |

$35.65

+

EU

Postage |

|

|

|

Magnet clip & 6ft (1.8M) wire (Option) |

CNC-EF-MAGNET & WIRE |

$5.95 |

|

|

Note: Specifications subject to change without

notice. The information in this document is believed to be accurate. Vancura

Innovations assumes no responsibility for possible printing errors and omissions.

![]()